If you’re thinking of replacing an existing oven or purchasing a new one, you will want to consider the best designed, quality oven on the market. We offer an unequaled history of performance, safety,reliability and quality construction. Our best compliments come from the most important people… our clients!

We did our homework and Steelman Ovens were clearly superior to all others on the market. Both the bake and burn-off ovens work flawlessly.

Manager of an electric equipment remanufacturer

We used to have problems with fires and explosions in our burn-off oven. Our new Steelman oven has eliminated those problems.

Paint line supervisor of a large manufacturing facility

We used to have the fire marshall and the EPA at our door regularly because of heavy smoke coming from our plant. Not anymore.

President of a rubber-to-steel manufacturing plant

We would like to hear from you to discuss your oven requirements. Please feel free to contact us for further information including video, specifications, and “How to Select a Burn-off Oven” booklet.

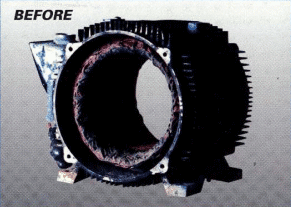

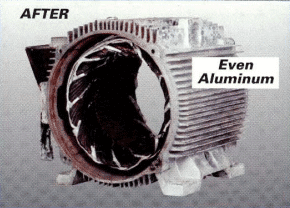

The Proof Is In Your Parts

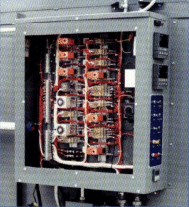

Automatic Process Control (APC)

APC makes oven operation totally automatic.

- Eliminates operator error

- Automatic cycle removes guesswork

- Uses high/low burner control

- Incorporates 3 level safety system

- Includes cool-down circuit

Industrial Quality Burners

All Steelman burn-off ovens include heavy-duty industrial quality cast iron burners.

Other manufacturers incorporate lighter duty sheet metal packages (some even manufacture their burners in-house).

- Built for industrial high temperature environments

- Available with inputs that exceed one million BTU/Hr

- Designed to produce less emissions

Durability & Reliability

Steelman burn-off ovens are built to significantly higher standards of durability than any other burn-off oven manufactured.

Our burn-off ovens are built to alleviate your concerns about corrosion, maintenance, downtime, efficiency and longevity.

- Angle iron & tubing frame

- Quality, brand name parts

- Exceeds NFPA & FM stds.

- 4″ Refractory & ceramic floor

- 5 layer wall protection

- Thoroughly tested at factory

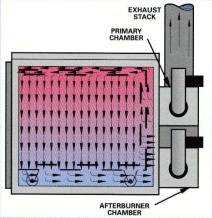

Top/Down Heating

This patented technology is the reverse of our competitors’ bottom-fired design, which evolved from incinerator technology.

Heating and controlling from the top has many benefits:

- Prevents damage to parts

- Reduces cart & wheel damage

- Improves operating efficiency

- Lowers emissions

- Provides uniform temperatures

- Allows ash pans in carts

- Eliminates combustion chamber damage & regular maintenance

Rate of Change Control

RCC allows our ovens to process large quantities of material quickly, without a fire hazard.

- Not a “Ramp & Soak” control

- No programming or menu selection required

- Monitors oven and afterburner

- Primary and backup water sprays and safety shutoff

High-Fire Afterburner

The high-fire afterburner heats up rapidly to 1500° F with a 1/2 second residence time. This benefit is included as standard (environmentally preferred).

- Meets current & future air quality standards

- Assures that the afterburner is ready to process vapors at a maximum rate

- Reduces cycle times

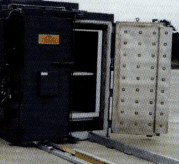

Folding Cart Tracks

Steelman oven tracks are built in a hinged assembly which allows the doors to be opened or closed over the tracks.

Other manufacturers’ designs require the operator to completely remove and replace tracks during loading and unloading procedures.

- Lessens possibility of back injuries

- Requires less work of operators

- Allows quick access to oven

You can avoid these problems…

- Fires and Explosions

- Damaged Parts

- Downtime & Maintenance

- Incomplete Runs & Poor Results

- Unwanted and Unlawful Emissions

- Poor Service & Factory Support

Purchase the solutions by Steelman:

- Patented Rate of Change Control

- Automatic Process Control

- Patented Top/Down Heating

- High Fire Afterburner

- Quality Components & Construction

- Professional Service