Oven Selection

To select a heat-cleaning oven, you need to determine the correct size and appropriate features for your application.

Oven Size

The oven must be sized to accommodate the largest pieces to be cleaned, and the quantity of parts necessary to keep up with production. The oven must be large enough to allow spaces between the parts for hot burner gases and cooling water spray to circulate. The manufacturer should be able to help select the correct size for your application. Computer-aided design systems may be used to lay out complex shapes.

Paint and Powder

Cycle times generally run 2 to 4 hours for paint and powder fixtures depending on the amount and type of coating on the fixtures and the oven temperature. Allow an additional 30 minutes for loading, unloading and washing. If 100 fixtures must be cleaned each hour, then the oven should be sized to hold 250 to 450 pieces. Allow a space equal to one diameter between fixtures for hot gas and cooling water spray to circulate.

It is generally more time and energy efficient to clean large loads rather than small loads because of the additional time required for loading, heating, cooling and unloading multiple loads. If extra fixtures are available for production runs, a larger oven may be more economical than a smaller one.

Electric Motor Rewind

The oven should be sized to hold the largest core to be stripped and allow 12″ between cores when more than one is loaded. This spacing will prevent the heat released from a core from damaging the ones next to or above it.

Automotive Engine and Parts Rebuilding

Allow sufficient space for hot gases to circulate between parts. Stack parts with flat surfaces, like heads, randomly or rotate alternate layers 90 degrees for best circulation. It is faster to process smaller loads with adequate spacing than full loads where the gas circulation is impeded.

Plastics Processing

Allow one inch or more between parts for circulation and 12 inches or more for items with a heavy coating of plastic.

Oven Features

Important features for heat-cleaning ovens include fire prevention systems, cycle time control, heating method, combustion chamber location, afterburner design, burner type, burner control stack construction, wall construction, pressure relief door design and cycle times.

Fire Prevention Systems

The most important heat-cleaning oven feature is the fire prevention system. Heat-cleaning ovens do not actually burn-off the coating and other contaminants because the parts would become extremely hot causing them to warp or melt. Instead, the ovens thermally decompose the volatile solids into a combustible vapor in a low oxygen atmosphere to inhibit combustion, and then destroy this vapor in an integral afterburner. If vapor is produced too rapidly, an ignition may occur in the oven, causing the release of smoke into the shop. Excess amounts of vapor can also overload the afterburner causing smoke to come out of the exhaust stack. Even a very large capacity afterburner can be overloaded if a fire occurs in the oven. Fire prevention systems fall into 3 groups: (1) single set point, (2) variable set point (ramp and soak) and (3) dynamic response.

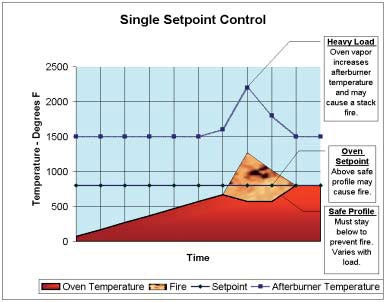

Single Setpoint System (see Figure 1). A single setpoint system allows the combustible vapor to ignite, which drives the oven temperature above the maximum temperature setting. A temperature switch turns on water sprays to put out the fire.

This method allows a fire to start, which can be difficult to control. Smoke may overload the afterburner or leak out of the doors. Single setpoint systems should only be used for very light combustible loads.

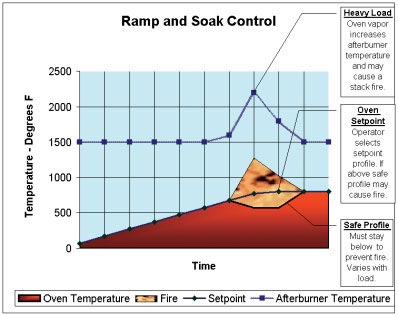

Ramp-and-Soak Control (see Figure 2). A ramp-and-soak control system is a refinement of the fixed set point system. The ramp-and-soak type controller increases the oven temperature over a fixed time period (ramp) until the final processing temperature is reached then holds that temperature for a predetermined time (soak) to complete the decomposition process. The ramp-and-soak profile is usually programmed by an operator or selected from a menu that includes a number of profiles. The operator must estimate the amount of combustible material in the load, which may be difficult. Formulas are not available to tell the operator how fast to ramp and how long to soak. If the wrong profile is selected, the temperature may increase too rapidly, causing a fire, or the oven may shut off too soon allowing smoke to come out of the stack. This system allows a fire to start before it responds. Because this system does not monitor the stack temperature, a stack fire is also possible.

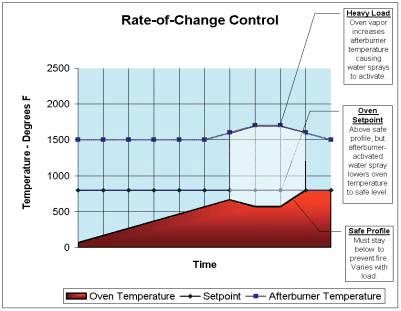

Dynamic Response System (see Figure 3). Dynamic response systems actually monitor the combustible vapor concentration in the oven and control it at a safe level. They respond to the load and do not require the operator to make any decisions. If the load does not produce excessive vapor, cooling does not occur. As a result, cycle times are as short as possible. Two dynamic response systems have been developed. The first, developed in the early 1980’s, uses the afterburner temperature as a measure of the vapor concentration in the oven. The vapor produced in the oven causes the afterburner temperature to rise when it is burned. If the afterburner temperature exceeds a preset limit, indicating that the vapor concentration has reached the maximum safe level, water sprays are turned on to cool the load and slow the process. Since combustible vapor can be produced before the afterburner reaches it’s normal temperature, the processing rate must be controlled at a relatively low level to prevent fires from occurring. The latest development in dynamic response systems is the Rate-of-Change Control system (Figure 3) (U.S. Patent 5,189,963). Rate-of-Change control is a factoryprogrammed system that continuously monitors the heat-up rate of both the oven chamber and the afterburner. If either heats up too rapidly, indicating excessive combustible vapor, the load is cooled until the heat-up rate is acceptable. The system is working from the moment the process starts, giving far better indication of vapor concentration than the earlier system. As a result, the controls may be set to give much greater processing rates. Rate-of-change control is one of Steelman’s patents.

Cycle Time Control

There are three methods commonly used to control cycle time. These are (1) batch timer, (2) ramp-and-soak timer and (3) automatic cycle timer.

- Batch Timer. The basic cycle time method is a batch timer, which requires the operator to select the length of time that the oven will run. This method requires a skilled operator to estimate the required cycle time. If the operator underestimates the cycle time required to process the load, the oven will shut off while it is processing. The result can be partially cleaned parts and possibly the emission of smoke from the exhaust stack. To avoid this, operators often add extra time to the normal cycle, which results in wasted time and fuel.

- Ramp-and-Soak Timer. Ramp-and-soak controllers often use the ramp plus soak time period as a cycle timer. This method also requires a skilled operator to examine the load and select the appropriate oven profile. It is still possible for the oven to shut off while it is processing vapor if the operator underestimates the soak time.

- Automatic Cycle Timer Dynamic response systems can sense when the oven is no longer producing combustible vapor and when the oven is up to the selected temperature. The oven can then be shut off without releasing smoke into the atmosphere. Because heatcleaning ovens have cool spots (usually in the floor near the front door) Steelman uses a second thermocouple located in the coolest part of the oven to assure that the parts are uniformly heated before the oven shuts off. The second thermocouple allows the oven to automatically adjust the cycle time to suit the weight of the load and remove the possibility of operator error. Steelman is the only oven manufacturer that uses two thermocouples in the automatic cycle timer circuit.

Heating Method

Most heat-cleaning ovens are heated by gas or oil burners rather than electric heaters. Burners produce low oxygen gases to help prevent oven fires, are less expensive to operate because gas costs less than electricity, and make superior afterburners because the vapor must pass directly through the burner flame.

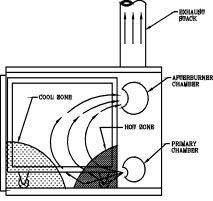

Bottom-Firing (see Figures 4 & 5). Most ovens have the primary (oven heating) burners in the bottom of the processing chamber and the secondary (afterburner) burners on the top (see Figure 4). Bottom-firing grew out of incinerator technology. It is the fastest way to burn materials in an oven, and the least expensive method of construction.

Some ovens have their primary combustion chambers in the bottom rear of the processing chamber, and try to throw hot gases under the cart or baskets holding the fixtures. These ovens may not process material in the front of the oven. Some have the combustion chamber under the cart or along one or both sides in an effort to improve distribution of heat to all parts of the oven. These ovens sometimes weaken and distort carts as well as valuable parts.

Bottom-firing is ideal for incinerators but less than ideal for heat cleaning ovens. Most ovens measure and control temperature at the top of the processing chamber; however, it may be much hotter near the combustion chamber outlet. Temperatures in this hot zone can reach 1,200°F or more (see Figure 5). This can cause overheating of parts placed too close to the combustion chamber in a bottom fired oven.

Aluminum and other temperature sensitive parts should be placed away from the combustion chamber outlet. Heavy coatings can drip into bottom-fired chambers increasing the possibility of fires. Because hot air rises, much of it may escape out of the top mounted afterburner without completely heating the load. This is the thermal equivalent of a short circuit.

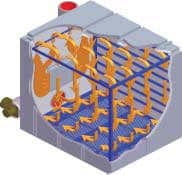

Top-Down Heating (see Figure 6). A relatively new technology called “Top-Down Heating” (U.S. Patent 5,189,963) has literally turned burn-off oven design upside down by introducing the heat in the top of the oven and removing cooler gases and combustible vapor from the bottom (see Figure 6). “Top-Down Heating” is a Steelman exclusive which has a number of advantages over bottom fired designs:

- The hottest spot in the oven is at the top where the controlling thermocouple is located. This is an important consideration when stripping temperature-sensitive parts such as aluminum, which may be damaged by extreme temperatures. Even steel will warp and deteriorate if it gets too hot.

- The hot, low density gases spread out over the length and width of the oven resulting in uniform temperature distribution. In bottom-fired ovens, the hot gases often rise to the top and exit through the afterburner before they reach all parts of the oven (short circuit).

- The heat is trapped in the oven and must pass through the load before exiting from the bottom. It cannot short circuit up the afterburner. This means higher efficiency.

- The heat moves downward progressively making the process easier to control. Bottom-fired ovens, like incinerators, try to set everything on fire at once.

Water sprays are located in the top of the oven, so they cool the hot combustion gases before they contact the parts, making the process easier to control. - The hot burner gases spread out before moving downward through the parts. This results in lower velocity gases, which stir up less ash than the high velocity gases from bottom-fired combustion chambers.

- Combustible vapors are dense and naturally sink to the floor where they are removed by natural draft into the afterburner. In a bottom-fired oven the vapor continuously mixes with burner gases resulting in higher concentrations in the oven, increasing the fire potential.

- Carts can be built with pans in the bottom (standard with Steelman ovens) to catch ash and drips that may fall from the parts. Also, baskets can sit directly on the floor. Pans and baskets would block the gas flow in a bottomfired oven.

- Cart wheels are not blasted with hot combustion gases as in a bottom-fired oven, therefore, they last much longer.

Combustion Chamber Location

Combustion chambers may be located inside the oven or outside. They may be on a rear or side wall, behind or under the cart. Careless loading or falling parts often damage inside chambers. Outside chambers cannot be damaged this way (see Figure 7). However, outside chambers should be enclosed in sheet metal to prevent damage to the chambers and to protect personnel from the hot surface. All Steelman Burn-off Ovens have enclosed external combustion chambers.

Afterburner Design

You need to be sure that the oven you are considering will meet current and future air quality regulations. The most important device for low emissions is the afterburner.

As mentioned previously, the organic materials in paint, powder coating, varnish, oil and grease, and plastics thermally decompose into hydrocarbon compounds in the oven. Because this vapor, or smoke, should not be discharged to the atmosphere, it is burned in the afterburner to produce primarily carbon dioxide and water vapor.

An afterburner is an insulated chamber where the oven vapor is mixed with air and heated to a temperature sufficient to destroy organic materials. Generally, higher temperatures and longer dwell times give lower emissions. Elements such as the chlorine in PVC and fluorine in fluoropolymers will not be destroyed in the afterburner and will pass into the atmosphere. Usually, these levels are below allowable limits; however, you should verify this with your state air quality agency.

The afterburner can be improved by using a temperature controller and an additional gas valve or modulating gas valve to increase the gas flow below 1500°F, a standard on Steelman ovens. This allows the afterburner to heat up rapidly and maintain the minimum operating temperature.

Most states require a minimum temperature of 1,400°F at the 1/2 second point of the afterburner (see Figure 7), which gives the vapor at least a 1/2 second dwell time at the required temperature. Some states require 1,500°F. Others require that the afterburner reach 1,400°F within 15 minutes. Many ovens do not meet these standards, especially the dwell time requirement. Be sure the controlling thermocouple is located at the 1/2 second point. Because air quality regulations are becoming more stringent, it makes sense to buy a high-performance afterburner.

Afterburners should have a processing capacity that will handle the maximum possible vapor load from the oven; otherwise, smoke will be emitted from the stack. Dynamic response systems, like rate-of-change control, automatically limit the oven processing rate to within the afterburner capacity. Other systems may require an afterburner with greater capacity to handle sudden large vapor loads. Large afterburners use more fuel and cost more to operate than standard afterburners. Be suspicious of a manufacturer who offers a large afterburner to increase processing speed without rate-of-change control. Even a very large afterburner can be overloaded without a system to control processing rate.

A good feature for a heat-cleaning oven is a cool-down circuit that turns on the water sprays to cool the load and prevent smoke from going up the stack in the event of an afterburner failure. The cool-down circuit should have a temperature switch that turns the water off when the oven is cool to prevent flooding the oven. This system is standard on Steelman Heat-Cleaning Ovens.

Burner Type

Burners are available in many different designs and materials. The most common burners are fabricated from light gauge sheet metal.

This incinerator-type burner has been used in many ovens over the years and is suitable for light-duty primary and secondary chambers where the steel temperature doesn’t exceed approximately 1,000°F. They can be used at higher temperatures, but the expected service life of the burner will be shortened.

Oven with high firing rates and elevated chamber temperatures like heat-cleaning ovens should use heavy-gauge sheet metal or cast iron burners with cast iron, alloy steel or refractory firing tubes. These industrial-duty burners have greater output, better air control, and lower emissions than the light duty incinerator-type burners often used on heat-cleaning ovens. Often, sheet metal burners cannot meet the 1/2 second dwell time required for afterburners. All Steelman Heat-Cleaning ovens have industrial-duty burners manufactured by Eclipse or Hauck, two of the best in the business (see Figure 8).

Burner Control

There are two ways to control oven temperature with the primary burner. First, the burner may be turned on and off at set point, requiring it to restart many times during a run. A better way is to leave the burner on all the time and reduce and increase the gas flow at set point. This high-low firing method reduces the number of lighting failures, wear on the burner components and actually makes the oven process with greater speed and safety. This is the method used by Steelman (see Figure 9).

Stack Construction

Insulated exhaust stack is necessary to discharge the hot gas from the afterburner into the atmosphere. The stack should terminate at least 3 feet above the roof. Local codes and National Fire Protection Association (NFPA) standards may require it to be higher. The oven manufacturer should be able to help layout the stack for your installation.

Exhaust stack is available in two basic forms: heavy steel pipe with hard refractory lining or light-gauge steel with ceramic fiber lining. The heavy refractory type requires a crane to set it in place. It is self supporting and requires no additional supports. The lightweight stack is usually available in 36 inch long sections, which can be assembled by two people. Hangers, or some other means must be used to support tall stacks and horizontal runs. Light weight stack is available with a galvanized or stainless steel shell. The stainless steel lasts much longer than galvanized steel.

Some manufacturers splice 12″ long sleeves together to make a 36″ “section”. Steelman exhaust stack is made with 36″ long ceramic fiber sleeves to eliminate “burnout” (see Figure 10).

Wall Construction

Most ovens have a structural steel frame and sheet steel walls. Oven manufacturers have standard thickness walls ranging from 16-gauge (approx. 1/16” thick) to 12-gauge (approx.7/64” thick). Generally, the heavy-gauge steel withstands attacks by water or corrosive substance better than light-gauge steel.

The atmosphere inside burn-off ovens is a hostile environment. Extreme temperatures, water sprays and organic or hydrochloric acid formed from decomposing compounds can damage the oven walls which may be expensive to repair. When the walls are protected properly, the oven will last for many years. Usually, a coating ranging from paint to an asphalt mastic protects the inside surface of the steel shell. A vapor barrier that prevents corrosive vapors from condensing on the wall will provide additional protection.

The coating and vapor barrier must be protected from the oven heat with insulation. Usually, 2 to 3 inches of mineral wool is used. Most manufacturers add rigid board or hightemperature ceramic fiber (1/4” to 1” thick) to the inside surface for additional heat retention and to protect the mineral wool from high temperatures. The board loses it’s strength after exposure to oven temperatures, and fixtures or other parts can tear the ceramic fiber when the cart or baskets are moved. Because the insulation can be easily damaged, it’s a good idea to line the inside wall with expanded steel or perforated aluminized steel sheet. If the insulation is ever damaged during operation, it should be repaired immediately to prevent damage to the vapor barrier and protective coating.

Steelman uses a mastic coating, a vapor barrier, 2 1/2” of mineral wool, 1” of ceramic fiber, and protects the entire interior with a steel liner for longer life. Steelman offers optional solid liners in aluminized steel or stainless steel for corrosive applications.

Pressure Relief Door Design

The NFPA requires that heat-cleaning ovens have a means to relieve pressure from the oven in the event of an ignition. These devices may be in the form of a spring-loaded front door or a gravity-loaded top door. The top door has the advantage of opening just far enough to relieve pressure and then closing automatically by gravity to keep smoke in the oven and oxygen out. Also, the hot gases will be directed away from the operator. The opening area should be 1 square foot for each 15 cubic feet of oven volume. Steelman uses the top door method.

Cycle Times

Oven manufacturers make many claims about cycle times for their ovens. Low numbers – like 1 to 2 hours -will probably be for loads with a very small amount of combustible material. In an actual production environment the cycle times may be longer than that. You should contact customers with applications similar to yours to verify that cycle times are as short as the manufacturer claims. To get a good estimate of cycle times, ship a full load of parts to the oven manufacturer for testing. Steelman Heat-Cleaning Ovens use the automatic cycle timer for the shortest cycle times.

- Paint and Powder Coating. As mentioned previously, it takes between 2 and 4 hours to clean paint and powder coating fixtures.

- Electric Motor Rewind. Electric motor stators can be stripped in 4 to 8 hours depending on the processing temperature and the amount of combustible material. Today, many electric motor rebuilders are following standards set by the Electrical Apparatus Service Association (EASA) and limiting stator temperature to 775°F or lower. Motors stripped at these temperatures require more time than those processed at higher temperatures. It’s a good idea to use a magnetic part temperature control thermocouple that will turn on water sprays if the stator releases heat, which is common with epoxy encapsulated motors.

- Automotive. An oven load of automotive engines and blocks can be cleaned in 5 to 8 hours depending on processing temperature.

- Plastics Processing. Screws can be cleaned in 2 to 3 hours. Dies usually take longer because the plastic is inside the cavities.

- Other Considerations. Sometimes fast cycle times are achieved by overheating parts located in the bottom of the cart, or by operating without a fire protection system, which may create a hazard. Remember, there’s nothing faster than a fire. Some manufacturers will offer a large-capacity afterburner to increase the processing speed of their ovens. If the afterburner is adequately sized to handle the vapor load from the oven, as discussed earlier, increasing the capacity of the afterburner will not speed up the oven.

Generally, shorter cycle times are achieved by increasing the burner gas inputs. Comparing manufacturer’s actual burner input – not rated input – will help you determine relative processing rates.

Other Features

There are many standard and optional features that are available for heat-cleaning ovens. Standard features for Steelman Heat-Cleaning Ovens include:

- Underwriters Laboratories (UL) Listed control panels.

- Factory Mutual (FM), American Gas Association (AGA) approved components.

- Fold-down tracks.

- Center door latches.

- Water spray seconds counter.

- Pilot lights for critical components.

- Terminal strips in control panels.

- Ladder-logic wiring diagrams.

- Gas pressure gauges for each valve train.

Optional components include:

- Powered cart movers.

- Battery backup water spray systems.

- Automatic door locks.

- Chart recorders.

- Part temperature controllers.